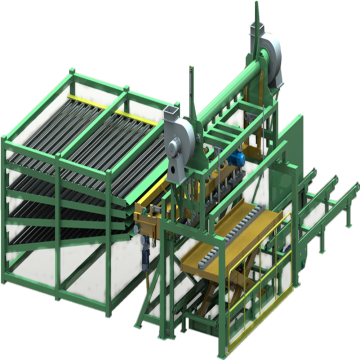

Prominent Features of Veneer Roller Dryer

Product Description

Product Description

The veneer roller dryer plays a very important role in producing the good quality veneer for the gluing and pressing in the plywood making line. Some outstanding features are:

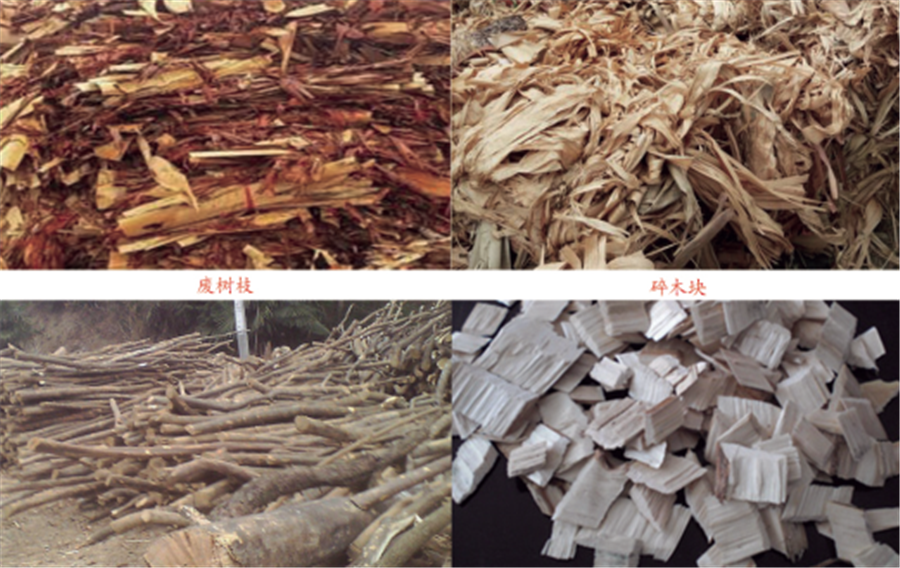

The biomass burner independently developed by our company can use the black wood, white skin, saw head and other waste wood materials produced by veneer peeling machine as fuel, so as to achieve local materials and turn waste into treasure. It greatly reduces the energy cost in the drying process of the veneer, and is a truly energy-saving and environmentally friendly heating device for the veneer dryer.

Automatic veneer feeder and veneer collection system are the first invented automatic veneer feeding and collection system for core veneer dryer machine in China. Only 1 person is needed at the feeding section of the wood veneer drying machine to solve the problem of many labor cost in the feeding and collecting dried veneer.

The surface of the rollers has been treated with high surface finish, which can effectively protect the veneer, and the concentricity of the roller is within 0.5mm; Bearing high temperature resistance of 500 degrees, low temperature resistance of minus 20 degrees, free of oil injection and maintenance for life. The dryers we produced have passed the CE certification.

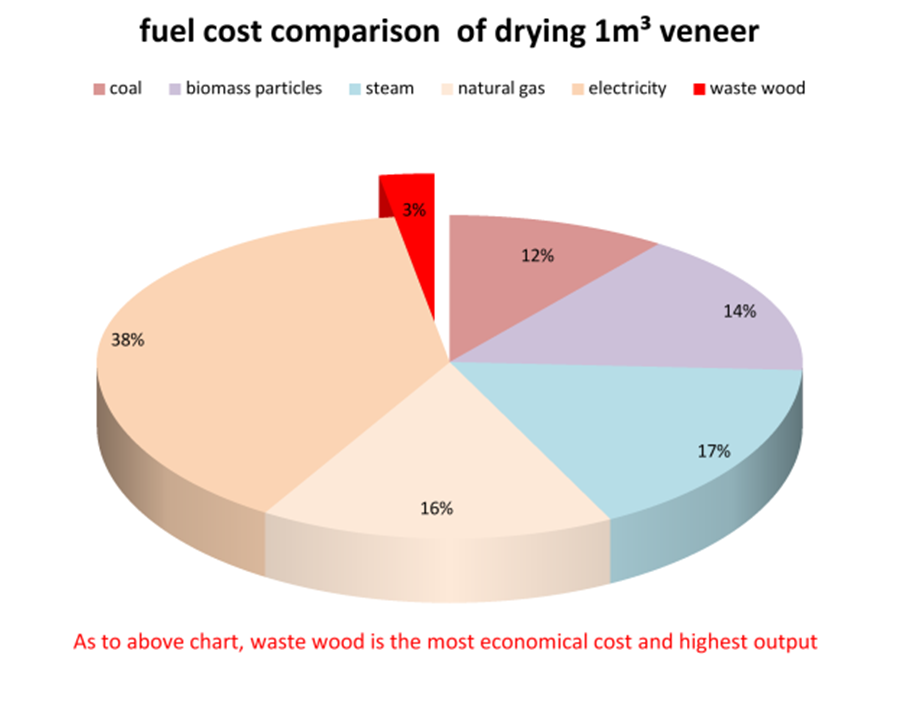

The biomass burner is the exclusive patent invented by Shine Machinery in China. It can burn all kinds of waste wood directly to reduce the fuel cost to the most. It has the advantages of high efficiency, low fuel consumption and energy saving. Compared to steam boiler or heat conduction oil boiler dryer, the drying cost of the biomass burner is the lowest. Both the steam type and the heat conduction oil type dryer need customers to provide heat sources and boilers, not only the steam boiler and heat conduction oil boiler cost are much higher than our biomass burner, but also the fuel cost of steam and heat conduction oil are much higher than waste wood.

Technical Parameters

Our Customers

About our company

Shandong Shine Machinery Co., Ltd is a large-scale enterprise specializing in R&D and production of veneer rotary cutting and veneer dryer equipment under the Shandong Wanda Heavy Industry Co., Ltd. Since its inception, the company has been adhering to the vision of [making first-class corporate contributions, building first-rate enterprise talent, creating first-class corporate brand", implementing modern enterprise management system, using new sales concepts and service systems, and investing 20 million yuan in scientific research each year. It also combines industrial universities to study high-end technology, so that Shine's veneer dryer products are always at the forefront of the industry's technology.

Our Services

1. All kinds of mold can be made by customer's requirements

2. All prices are based on FOB.QINGDAO, China

3.Payment; by T/T or L/C.

4. All the Parameters above just for reference, for they are updating all the time

5.Package: Standard packing

6.Warranty: All the machine enjoys one year's warranty, in this period

7. Any problems with the machine, please feel free to contact us. We will try our best to make it.

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After-sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Categories : Veneer Dryer > 4 Deck Veneer Dryer